|

|

Visible rock before the drilling work,

where the antenna

system will be placed, project start September 2009. |

This telescopic aluminum tower from Cue Dee will be the base

in

the antenna system. |

|

|

Work to isolate the tower from ground has started up. |

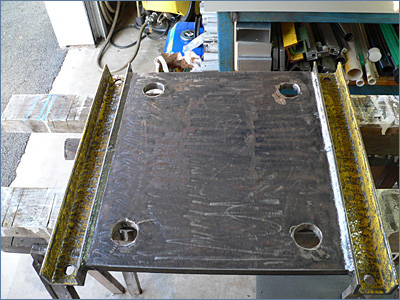

Old man cleaning up those 45 mm holes that where first done with a cutting torch in the 20 mm bottom steel plate. |

|

|

Some mig-welding work to fix the pieces at correct places. |

Close picture of one welded point and a 45 mm hole in the steel plate. |

|

|

Bottom steel plate welded all around and ready for painting. |

Welded with power and big electrodes. |

|

|

Göran Foghammar with his diamond drilling machine. |

My buddy Göran shows one of todays heavy drill cores. |

|

|

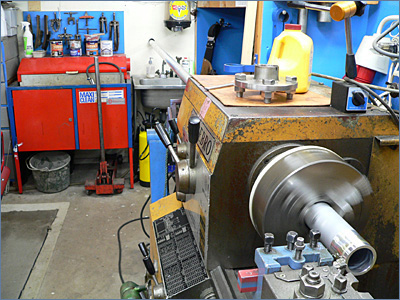

Drill work with the insulators in my Lathe. |

More work in the Lathe with the insulators. |

|

|

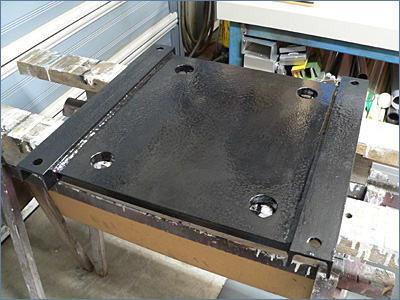

The bottom plate now painted and ready. |

Insulators to the vertical antenna tower. |

|

|

4 pieces of 15 mm thick steel washers to carry the

vertical antenna

tower from Cue Dee. |

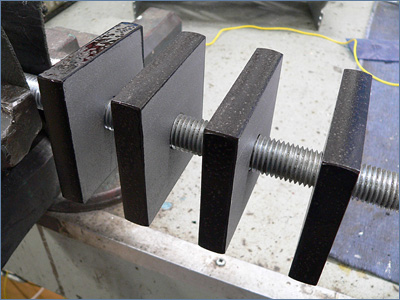

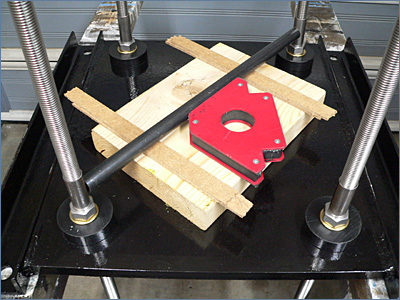

Some welding work to be done, just making a tool for concrete

constructional work. Stainless steel threaded rods in place. |

|

|

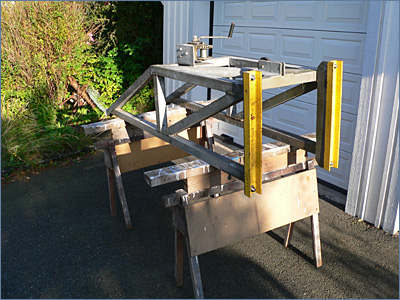

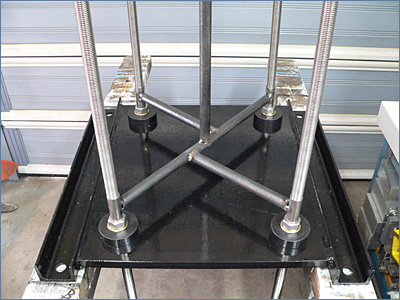

The tool is welded and ready! |

Ready for concrete constructional work! |

|

|

Old man in mixing business with a drilling machine. |

All holes filled up and the threaded rods still in place. |

|

|

A form to be filled with concrete is just produced and in place. |

Form is filled with concrete! |

|

|

Cleaning up the area where the tower will lay down. |

Husky chainsaw, a typical antenna tool? |

|

|

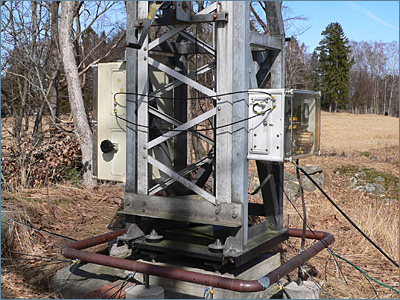

Concrete fundament finished, some parts in place. |

Steel plate mounted between insulators. |

|

|

Bottom part of the telescopic tower mounted and ready. |

SA6AMV (my son), Torbjörn "Linda" Lind and Stig "Stisse" Strömberg help me to mount the Cue Dee Alu-Tower. |

|

|

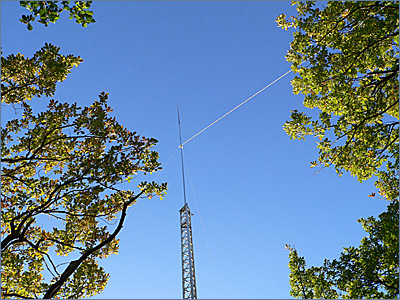

Tower mounted to the bottom part. |

Tower finally erected and a good way up in the air. |

|

|

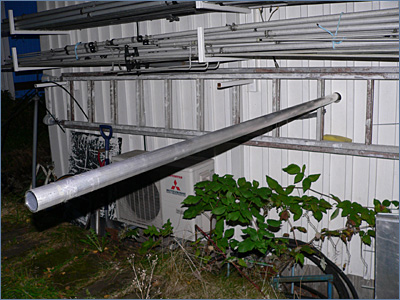

If the antenna pipe is too long, just make a hole in the wall,

6 meter 50 mm aluminum pipe in my Storebro Lathe. |

Other end of the aluminum pipe through the wall and outside the antenna workshop... ;-) |

|

|

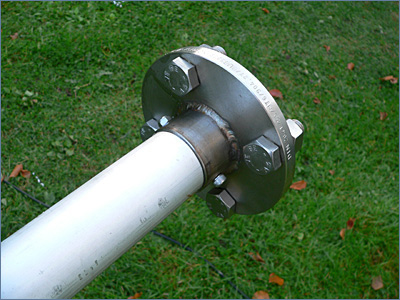

Connection to the top pipe in the tower. |

All pipes delivered to antenna place, 18 meter on top of tower. |

|

|

Alu-plate on top of the Cue Dee telescope tower. |

The stack of oak wood grows every day! |

|

|

Connection to the top pipe in the tower instead of a rotator. |

Tower antenna without top-cap, a total length of 24 meter. |

|

|

Test with a fishing rod in the top, total length 30 meter. |

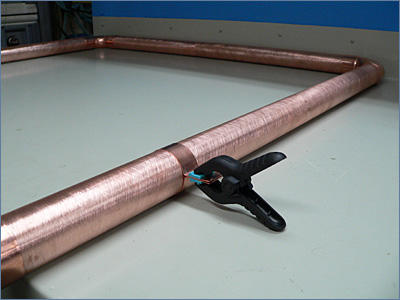

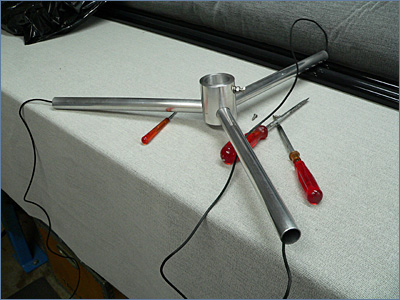

Center part of ground plane system on the planning board. |

|

|

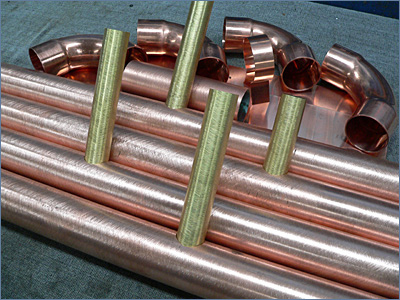

Copper and brass pipes to be welded together. |

And here's the result, brass pipes to carry the copper frame! |

|

|

Copper frame in center position. |

Paper tubes filled with concrete and frame in balance. |

|

|

Old man with ground plane wire drum, waiting for the boat. |

Young man, SA6AMV-Henrik, captain of the boat. |

|

|

View from the boat when we were dropping wires! |

The center with the growing amount of wires! |

|

|

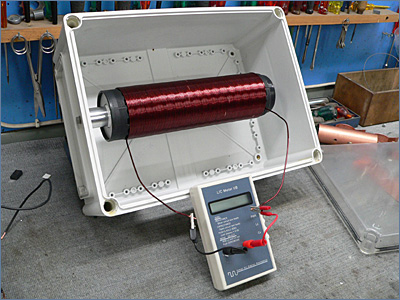

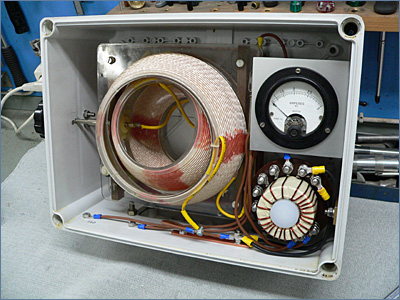

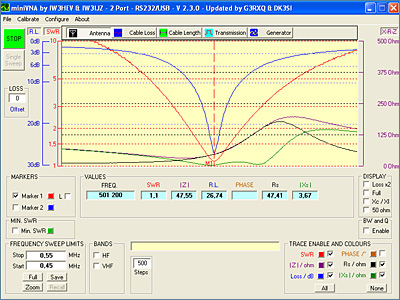

ATU # 1 under construction... |

Coil is almost finished, check with the AADE LC-meter. |

|

|

ATU # 1 installated and

ready for more adjustments... |

Center part of the top-cap under construction. |

|

|

Top cap in mother nature, one fishing rod in place. |

All three fishing rods mounted with copper wire inside. |

|

|

Picture from the top side. |

Top cap 24 meter up and seems to work ok now. |

|

|

More and more wires connected to the copper pipes. |

New top-cap on the workbench, to be like a giant umbrella. |

|

|

Angle grinder to cut out the profile from 5 mm al-plate. |

The center is ready, only the fishing rods is missing. |

|

|

Photo from top side of the new top-cap center. |

Picture of the new Top-cap with 6 meter foldable fishing rods. |

|

|

Nice picture of the antenna system at sunset in december. |

New ATU # 2 under construction... |

|

|

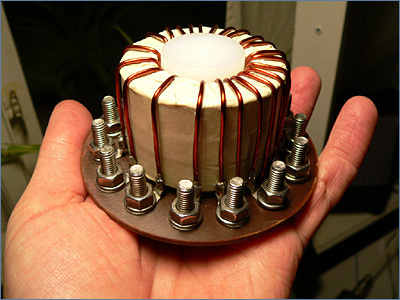

A handy matching transformer... |

ATU # 2 completed. |

|

|

ATU # 2 installed a cold

december day, works just fine! |

View from lake side winter 2009-2010.

|

|

|

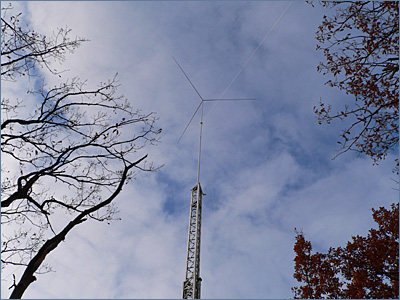

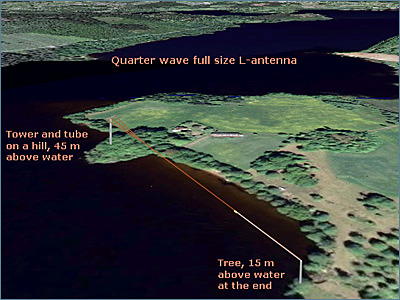

New L-Antenna in the air october 2010, works great! |

5 oak trees down to free a gate for the L-antenna wire. |

|

|

| No need for a variometer anymore, just a wire in the air. |

Another view from the lake side, antenna and station house. |

|

|

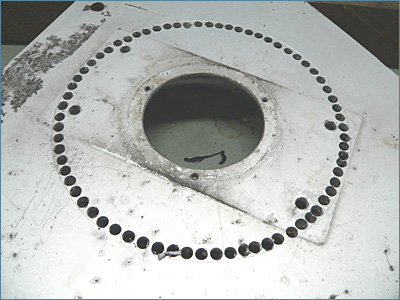

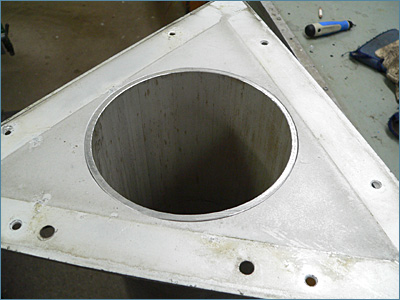

| Modification of the tower to get a bit higher up... :-) |

Top plate ready with a new 150 mm hole. |

|

|

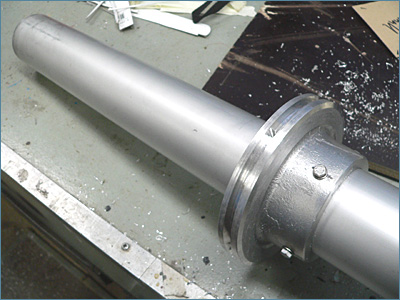

| Inside the top part of the new 150 mm aluminum tube. |

70 mm tube fits into the top part of the 150 mm tube. |

|

|

| Bottom part of the new big aluminum tube. |

This unwelded part is to be mounted at the top of the tower. |

|

|

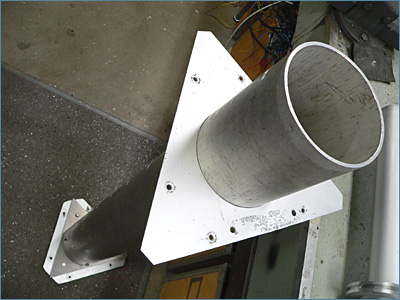

| Welding work to get the aluminum tubes together. |

Complete new part with a 70 mm aluminum tube inserted. |

|

|

| The new 150 mm tube connected to the tower. |

Telescopic top 12 meter tube connected to 150 mm tube,

XYL calling for medical help to the OM... ;-)

|

|

|

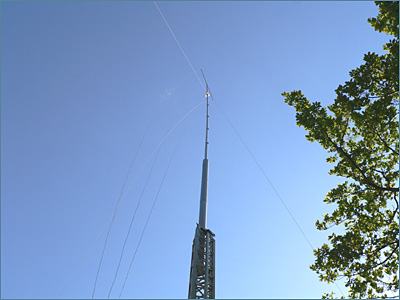

| Tower in the air, but not yet at top hight. |

Tower erected and works just fine! |

|

|

| My son SA6AMV digging to improve earth plane. |

Next hole in the ground, hardworking junior... |

|

|

| Aluminum disc in the ground connected to earth plane. |

New coil in the ATU for fine adjustment on 472 kHz. |

|

|

| New coilbox at backside of the tower for longwave work. |

Adding 980 uH gets the system in resonance at 136 kHz. |